Aiming to recycle 40K tons of wasted scallop shells from one of the largest scallop landings in Japan

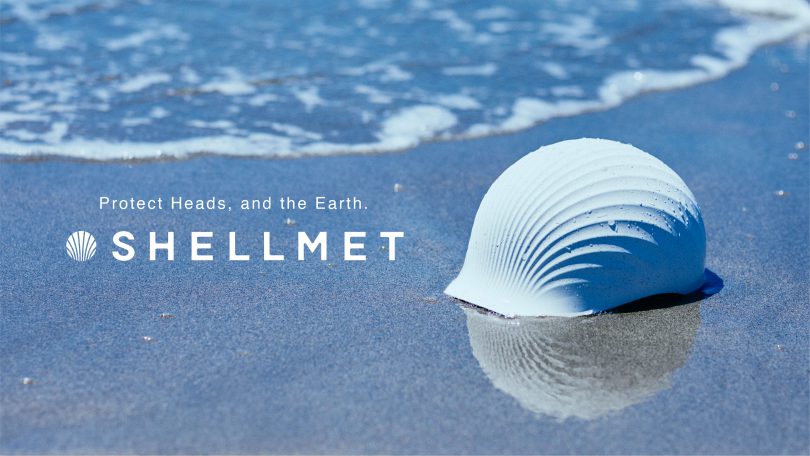

OSAKA, Japan, Jan. 10, 2023 — Koushi Chemical Industry (Osaka, Osaka; Representative Director: Akika Nambara; hereinafter referred to as “our company”) and Sarufutsu Village (Hokkaido; Mayor: Kouichi Ito; hereinafter referred to as “Sarufutsu Village”) present SHELLMET, the environmentally friendly helmet that is made by reusing scallop shells, a form of marine waste. In line with this announcement, pre-order sales of SHELLMET begins from 14 December 2022 through crowdfunding. Our company will utilize the ecoplastic manufacturing techniques that we have developed and work together with Sarufutsu Village, which aims to reduce the amount of plastic used, to further promote sustainable efforts by treating scallop shells as a valuable resource that serves as an alternative to plastic.

SHELLMET Development Background

Shells that have protected themselves from external enemies are reborn to protect people and the earth.

Among Japan’s domestic marine products, scallops have the largest export value. Sarufutsu Village is one of the leading producing areas of scallops in Japan, having repeatedly won the top prize for scallop catch in the country. On the other hand, the Soya district, where Sarufutsu Village is located, generates approximately 40,000 tons of shells as marine waste annually during the scallop processing produces.* With the export of scallop shells for reuse out of the country set to cease in 2021, the environmental impact of storing scallops on the ground and securing a place to deposit them have become social issues for the local community. In order to solve the problem of the village’s surplus scallop shells, our company focused on the fact that the main ingredient of scallop shells is calcium carbonate, and came up with the idea that they could be reused as a raw material for a completely new material. The project team started to develop the scallop shells as an important resource to support the village and began efforts to recycle the material.

*Fisheries Promotion Division, Fisheries Bureau, Hokkaido Department of Fisheries and Forestry, “Survey of Fisheries Waste Generation in FY2021”.

The original role of a shell is to protect itself from outside enemies, and since scallop fishing is a dangerous activity, the “SHELLMET” was born from the idea of making a helmet out of scallop shells to protect scallop fishermen. In recent years, Hokkaido has been hit by major earthquakes, and the risk of disasters such as heavy rain and snow damage due to abnormal weather has been increasing. From this fact, the team decided to commercialize the product not only for use by scallop fishermen, but also for use by villagers as disaster prevention helmets to protect themselves.

Inventing the new material from wasted scallop shells and waste plastic

Scallop Shells x Waste Plastic: Japan’s first new material* “Shellstic“, upcycled from waste

Our company is a long-established manufacturer of plastic products that was founded in 1969. Together with Professor Hiroshi Uyama from Osaka University, we began developing a new material based on scallop shells, whose main component is calcium carbonate, and recycled plastic. With the support of Sarufutsu Village, which has provided its excess shells, we developed “Shellstic (Combination of words “Shell” and “plastic”)”, a new recycled material that is comprised of roughly 20-50% each of scallop shells and waste plastic.

*The first material in Japan that combines scallop shells and waste plastic (based on our company’s research)

Characteristics of “Shellstic“

• Contributes to a maximum 36% reduction in CO2 emissions compared to the use of 100% new plastic

• Contributes to a 20% reduction in CO2 emissions compared to limestone-derived eco-plastics.

• By mixing scallop shells into the plastic, strength (bending modulus) is improved by about 33%.

Furthermore, because it is an upcycled material that utilizes waste, it is expected to reduce the amount of waste in the world and help solve the waste problem in the region.

Comments from Toshinori Kimura, Professor Emeritus at Hokkaido University and President of Japan Society of Biomass Industries

In Soya district, where Sarufutsu Village is located, and Hokkaido Prefecture as a whole, it cannot be denied that the problem of sustainably and effectively using shells that are produced as waste during processing has long been a major issue in scallop fishing areas.

Scallop and oyster shells that are separated out at processing factories for marine products are picked up and disposed of by disposal companies for a fee, but there are more than a few instances in which they are stacked in piles as they await disposal. Shells that are left in piles outdoors are becoming a common problem for scallop and oyster fishing areas, as they cause concerns related to foul odors and environmental impact. Although there are recent statistics that report that they have a high recycling rate, the truth of the matter is that a steady, effective method of use has yet to be established, even though they are being recycled for artificial reefs, construction material, manure, and various other uses. There were few cases of reuse as consumer goods, given the high costs to process the shells into a shape that makes them easy to recycle.

Under these circumstances, this product that has been developed using scallop shells and recycled plastic with a high ratio of shells mixed in and is expected to contribute to the circulation of resources and reduced CO2 emission. In addition, because it can be used casually by consumers, it could also represent a meaningful endeavor in the sense of raising environmental awareness among common people.

Characteristics of SHELLMET

“Biomimicry” design inspired from seashells

SHELLMET is developed based on the concept of “Biomimicry”, which is the application of the mechanisms of the natural world to technological development. SHELLMET incorporates a special rib structure in its design that mimics the structure of scallop shells, which is part of the material used for helmet production. As a result, the durability of SHELLMET is improved by about 30% compared to the case without the rib structure, even though less material is used.

From material development to design, the product is designed with sustainability in mind with minimal burden on the environment. SHELLMET upcycles scallop shells that would have otherwise been discarded. The product is available in a total of five color variations: CORAL WHITE, SAND CREAM, DEEP BLACK, OCEAN BLUE, and SUNSET PINK that imagine the colors of oceans. They can be used for a variety of purposes, including disaster prevention, work, and commuting by bicycle.

In conjunction with this announcement, a crowdfunding campaign will be launched on MAKUAKE for pre-order sales.

Upcoming Plans

In Sarufutsu Village, approximately 270 fishermen wear plastic helmets on a daily basis. We will promote the use of eco-plastic by using helmets made of shell-derived eco-plastic as a trial starting in the spring of 2023.

In addition, we plan to gradually develop “SHELLMET” by stockpiling it as a disaster prevention product, selling it to the general public, and introducing it as a tax return gift for hometowns ※ (※ Furusato Nozei: Japan’s tax reduction system for the taxpayers who donate to local municipalities). Through this initiative, we will promote the active use of reusable materials and raise awareness of disaster prevention among village residents.

Comments from Koushi Chemical Industry and Sarufutsu Village

Koushi Chemical Industry Co. Planning & Development Supervisor Tetsuya Nambara

Various new eco-plastics are currently being released under the theme of SDGs. However, the reality is that true eco-plastics that meet cost, quality, and sustainability requirements are very limited at this time. While new materials are being mass-produced, hundreds of thousands of tons of waste are incinerated or landfilled each year that could still be used. We believe that it is essential to recycle more waste than ever before in order to promote a sustainable society.

We are pleased to be able to collaborate with the people of Sarufutsu Village and help solve social issues in the region. We are committed to building a sustainable society that utilizes waste, and we hope that similar efforts will spread throughout Japan and around the world.

Sarufutsu Village Mayor Koichi Ito

The effective use of “scallop” shells, the treasure of Sarufutsu Village, has been sought for many years. We believe that we can contribute to the realization of a sustainable society if scallop shells, which have once finished their role of protecting itself from external enemies, can next be reborn and become a helmet to protect people’s heads. First, we plan to use them for fishermen and as disaster prevention equipment. Sarufutsu Village will continue to seek ways to realize a sustainable society, not limited to the use of Sarufutsu scallops.

SHELLMET Product Overview

Product name :SHELLMET

Distributor :Koushi Chemical Industry Co.

Pre-order date : December 14, 2022

Main sales date :Late March 2023 (scheduled)

Price : 4,800 JPY

Size :Accommodates head circumference 53-62 cm (adjustable with belt)

Color :CORAL WHITE (white) , SAND CREAM (beige) , DEEP BLACK (black),

ocean blue(Blue), sunset pink(Pink)

Official website URL : https://koushi-chem.co.jp/hotamet/en/

Concept movie URL: https://youtu.be/LkUOmIuFM_c

Crowdfunding Page URL:https://www.makuake.com/project/hotamet/

Koushi Chemical Industry and Sarufutsu Village Overviews

Koushi Chemical Industry

A plastic manufacturer located in Higashi-Osaka, founded in 1969. The company develops and produces parts for various products used in hospitals, offices, and convenience stores, as well as household goods. Koshi Chemical Industry Co. is actively involved in social contribution activities and donated more than 200,000 face shields to hospitals nationwide in cooperation with universities in the early days of the COVID-19. Amid calls for a sustainable society, as a company that utilizes petroleum-derived plastics, we are actively engaged in activities to “understand the good and bad of plastics and have a positive impact on society” as our responsibility. As an environmental protection activity that we can do right now, we are focusing on further promoting recycling and utilizing waste that can still be used but is thrown away. We will continue to take on the challenge of contributing to environmental protection and creating a better future through the wise use of materials.

Sarufutsu Village

Sarufutsu Village, which is located in northern Hokkaido, is the northernmost village in Japan. With a total area of 590km², it is the largest in Hokkaido. It also has the largest annual catch of natural scallops in Japan. It is a small village of 2,760 people that is full of surprises, including rivers with the legendary Sakhalin taimen and the Esanuka Line, which has straightaways of about 4km to the north and about 8km to the south and is beloved by riders for not having a single guardrail or utility poles along the way.